“One-to-Many” separate hopper loaders feature more functions, easy to operate, and convenient to install. Equipped with a high pressure blower and two to twelve OMH/OPH vacuum hoppers

189-4860-6110 / 0769-82020256 Online consultationNaming Principle

Features

“One-to-Two or One-to-Many” hopper loader greatly lowers the cost.

Dust collective chamber features a cyclone separator and a dust collective bin to effectively reduce the load of the filter and the dust content.

Separate dust collector is convenient for dust cleaning.

Complete safety protection function device, like material shortage and motor overloading alarm.

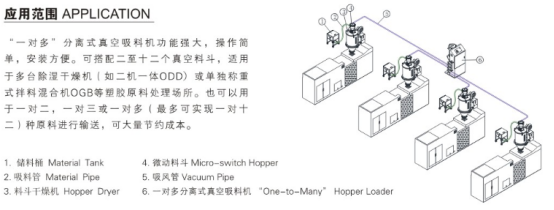

Application

“One-to-Many” separate hopper loaders feature more functions, easy to operate, and convenient to install. Equipped with a high pressure blower and two to twelve OMH/OPH vacuum hoppers, this model is applicable to many dehumidifying and drying machines (dehumidifying dryer “ODD”) or one gravimetric blenders “OGB” to process plastic materials. Besides that, it can also realize the “One-to-Two, One-to-Three or One-to-Many (as many as 12)” way of conveying materials to different molding machines or hopper to greatly lower the cost.

Function Scheme

The control device starts the vacuum motor to take out the air in the hopper, the material valve is closed meanwhile, thus negative pressure is created. With the function of negative pressure, material in the storage tank is delivered to the hopper through material pipe. The vacuum motor stops working when the suction time comes out, the material valve is opened by material, then material falls into injection machine or other equipment.

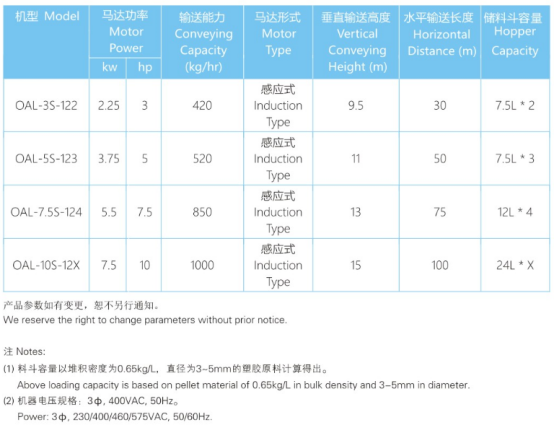

Parameters