Dehumidifying: damp and hot air from dry material barrel is blown into rotor after cooled. Moisture from the air is absorbed by rotor and is then absorbed by regeneration heating air.

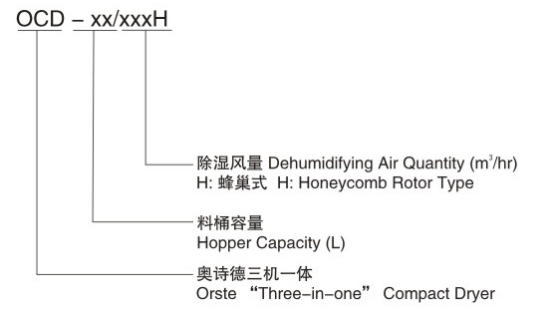

189-4860-6110 / 0769-82020256 Online consultationNaming Principle

Features

P.I.D temperature controller to accurately control regenerative temperature.

Adopt Japan Nichias molecular sieve honeycomb rotor which ensures good stable dehumidifying effect.

Detachable cooler is equipped, easy for maintenance and keeps a low return air temperature.

High density return air filter ensures no contamination to the honeycomb.

Equipped with double-layer insulated stainless steel drying hopper, adopt down-blowing drying air pipe design, ensures even drying of materials.

Vacuum take-off valve (can be quickly detached) is equipped in feeding system to ensure no surplus raw material in hopper tubes.

Heat material conveying can be equipped with closed loop hot air conveying device to avoid contamination and moisture regain.

Optical hopper dryers are optional to suit production of optical and food-grade product.

Transparent window design for filter makes it convenient to monitor the condition of filter. The cleaning or change of the filter can be done according to the actual need.

The clip style cover design ensures easy maintenance.

Dew point can be as low as -40oC.

For models below OCD-300/200H, air-cooling methods is optional, which ensures low energy-saving and convenient for movement.

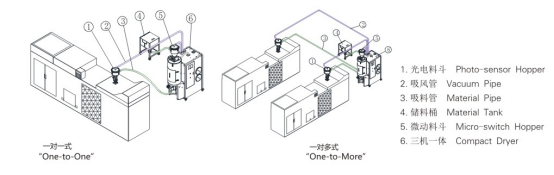

Functional Scheme

Dehumidifying: damp and hot air from dry material barrel is blown into rotor after cooled. Moisture from the air is absorbed by rotor and is then absorbed by regeneration heating air. Two strands of airflow function on the rotor. And with the rotation, moisture from the air is absorbed and expelled after absorbed regeneration air to form stable low dew-point air, which is dried to the drying temperature and then is blown into material barrel to closed circle to dry material.

Suction: material is absorbed into barrel from storage barrel or other storage containers. When the magnetic reed switch detects no material, suction motor runs to produce vacuum inside vacuum hopper. Raw material in storage barrels is absorbed into suction hopper due to air pressure difference. When material suction completes, motor stops. Raw materials drop into drying hopper barrel due to gravity. The dried raw material after dried is taken out to the hopper with photo-sensor installed on molding machine or other hopper from drying hopper barrel.

Application

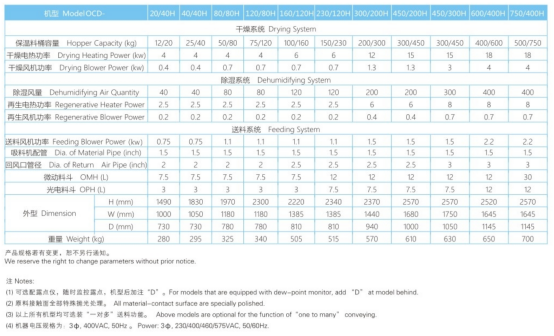

Parameters